Slice & print

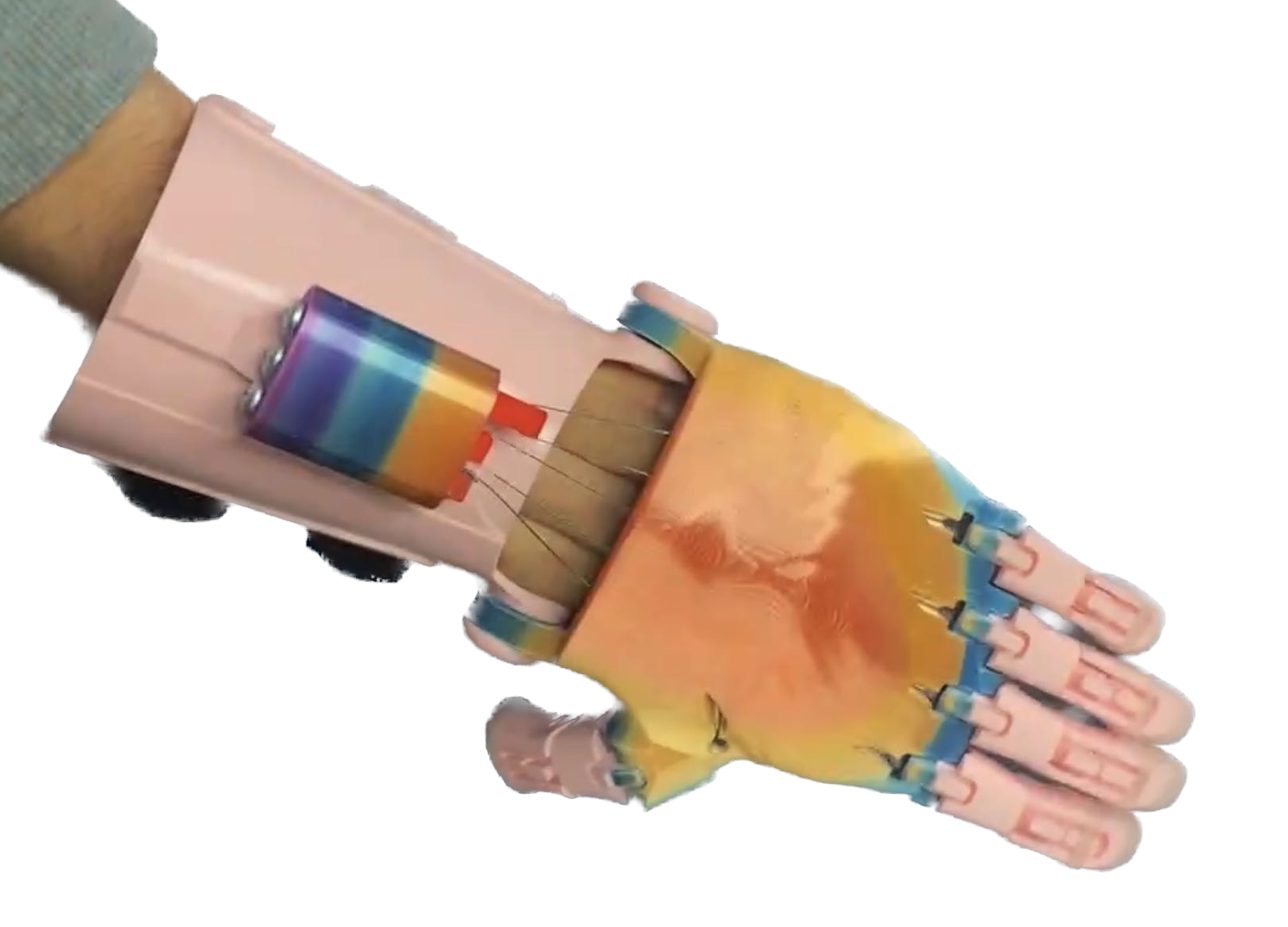

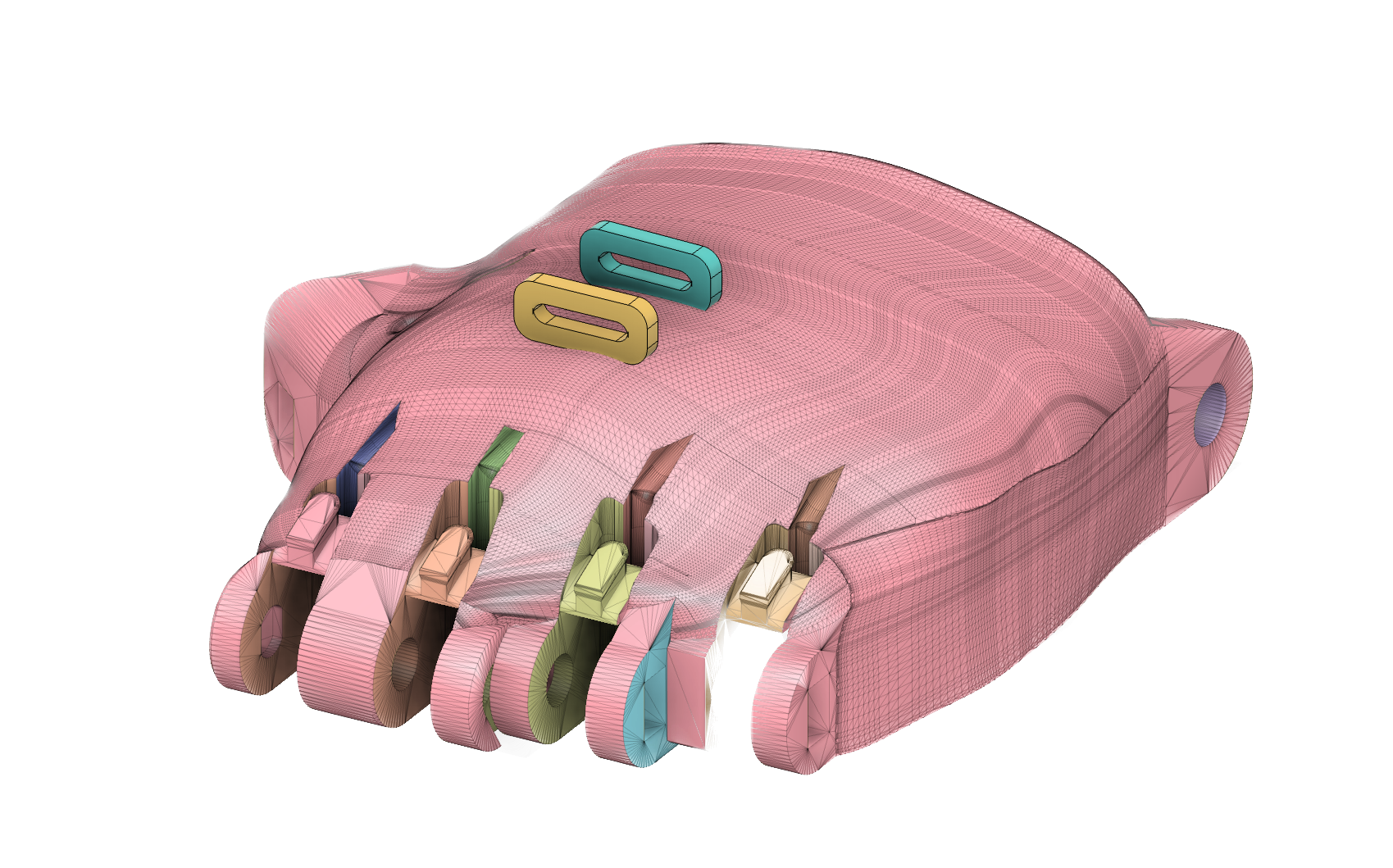

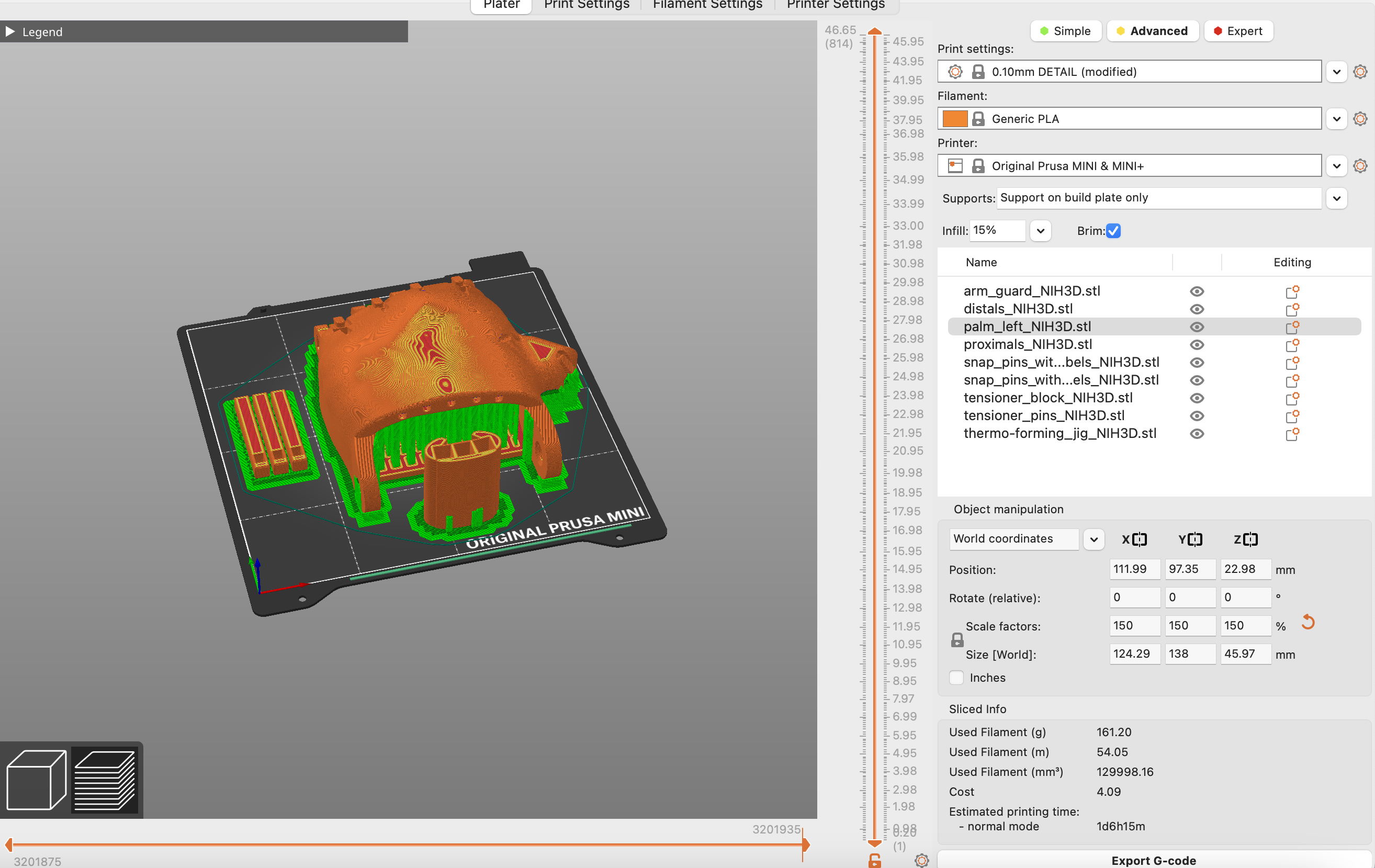

I first registered as a member of e-NABLE and download the presets of Unlimited Phoenix left hand version 3. I didn't use Raise E2, instead I used Prusa MINI, whose bed is relatively small, considering we were slicing 150% scaled components. Therefore, the whole set of components need to be allocated to two prints. I did one print and my partner did one. In the last project, one failure print was presumably caused by excessive supported. So this time I chose 'supprt on build plate only' instead of 'support everywhere'. And it came out pretty good.

On the day I was printing, almost all the printers experienced filament breakage due to increased indoor moisture. I had to figure out how to reload the PLA filament. Firstly, you should identify where the filament has broken. If it breaks between the filament sensor and the extruder, try to purge the broken part if possible and then unload the remaining broken filament. If the break occurs between the filament sensor and the filament spool, unload or purge the filament beyond the break and let the gear catch it once reloading begins